The Iconic Limestone Mill structure is one of the only remaining Mills in Central Pennsylvania that has an existing mill dam and machinery still intact. The Mill was recently listed on the National Register of Historic Places. The Mill Dam makes possible the future restoration of the mill as a unique example of early water powered mills in Cumberland County which were an essential part of the farming and early industry of the area.

The Mill and Mill dam were donated to Preservation Pennsylvania in 2019 from the estate of William Foshag, a preservationist who owned and maintained the mill from 1976 until his death. Preservation Pennsylvania established an in perpetuity historic preservation easement on the property which insures that all future owners of the dam and mill will preserve the historic integrity of the exterior of the mill. Fortunately for the community, a descendant of Howard T. Heishman, who owned the Mill from 1940 to 1947 agreed to purchase the mill from Preservation Pennsylvania and completed extensive renovation on the exterior of the mill. The new owners have been working closely with historical organizations and the Pennsylvania Fish and Boat Commission to provide safe public access to the Conodoguinet Creek Water Trail and provide a variety of historical and environmental programs to the community. The sign below was designed by The Design House, Marla Rozyckie for our Portage Project.

David Smith, Cumberland County Historical Society

Article Courtesy, David Smith, Cumberland County Historical Society

See Water-Powered Mills of Cumberland County Pennsylvania, 2015, Published by the Cumberland County Historical Society (Heishman’s Mill pgs. 114-117).

Historical Significance

The Diller-Heishman Mill dates to the beginning of the 19th century. It was constructed by Francis Diller, a German-Mennonite farmer. The family came from Lancaster County. In 1807 Diller leased the mill to Henry Snyder. Snyder received 1/3 of the cash from the toll grain. Diller received 2/3s of the cash and was responsible for keeping the mill in working order. Diller died in 1814 and passed the mill to his son, Francis Diller, Jr. He operated the mill until 1845. Tax records indicate there were two stills on the property. The property passed to Samuel Diller in 1845 and his partner John Greider, Sr. John Grieder, Jr. acquired the mill in 1868. By the end of the 19th century, the mill had been acquired by Curtis Keiter and then in 1920 by Benjamin F. Heishman, a miller from Baker, West Virginia.

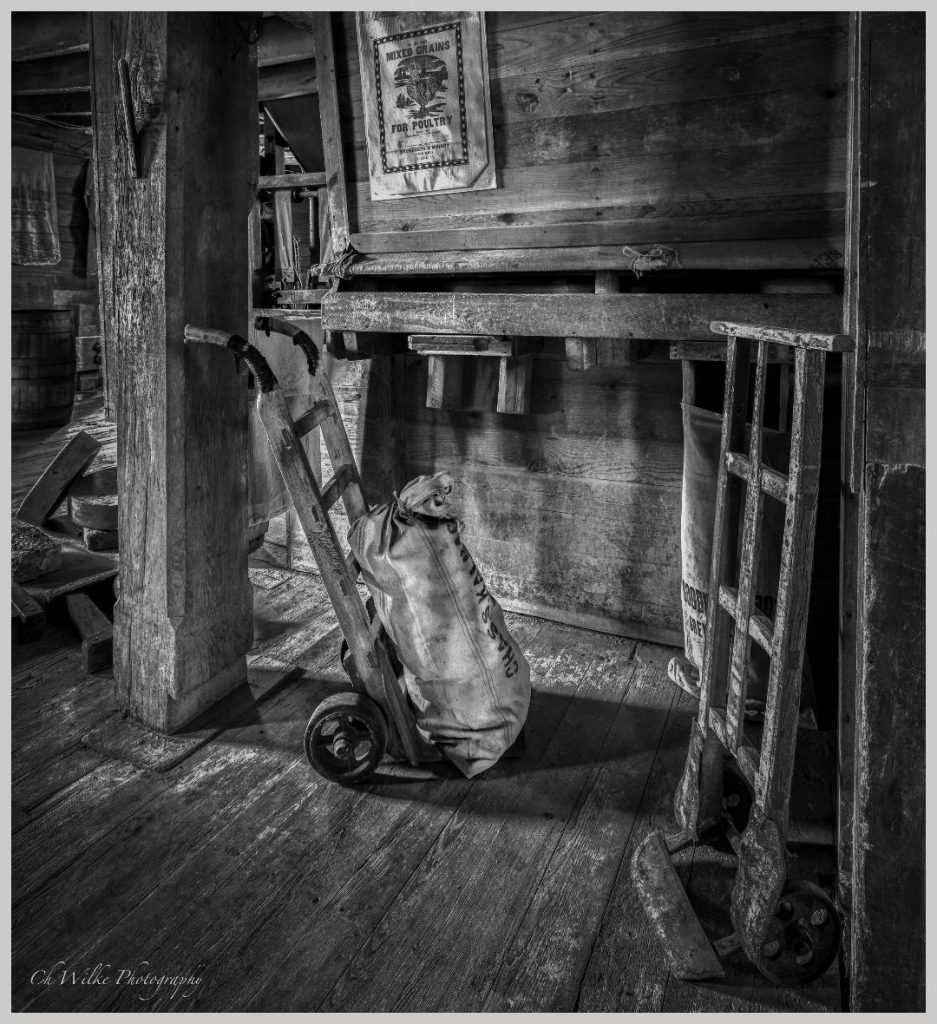

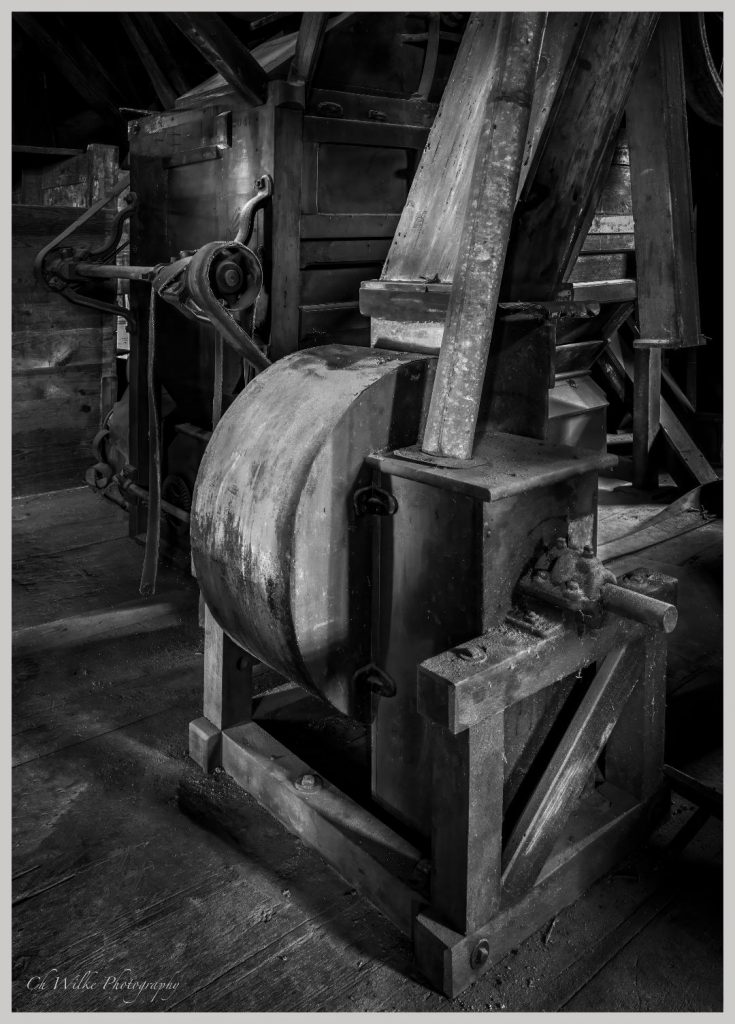

Heishman modernized the mill, a process that had begun by the Keiter family. Heishman also added the office, storeroom and the brick engine room. Heishman labeled his product, “Ladies Choice Flour.” He died in 1947. The mill was run by Howard T. Heishman from 1940-1947. From 1947 -1954 the mill was owned by Jesse B. and Dorothy Heuhauser and Morgan C. Wright. They ran the mill along with the Barnitz Mill in Dickinson Township. They continued with the “Ladies Choice Flour” production but also made “Sifted Snow” pastry flour, cornmeal and” Mixed Grains for Poultry.” Production at the mill declined in the mid 1950s and the final sale was recorded in September 1957. Ownership passed to Sarah Dorothy Neuhauser from 1954-1967, then to Bernard E. Reffner from 1967 – 1976 when it was acquired by William Foshag.

Of special notice is the mill’s association with famed itinerant wood carver, Wilhelm Schimmel (1817-1890). The German itinerant woodcarver used the mill as his home base for carving. He would stay for awhile and then leave for some time wandering to various locations. Some of the wood he carved would have been picked up at the Greider sawmill.

Architectural Description

The earliest section of the mill was built c.1806 but has been added onto and modified throughout the 19th century. William Foshag restored the mill toward the end of the 20th century. The mill property currently includes the mill building, the timber-crib mill dam, the lower millpond west of the mill, the tailrace which runs under the mill and flows to the east. The two-story miller’s house also stands across the street including a log section to the west and a brick section to the east. The house is no longer part of the mill property and is on a separate deed.

The mill dam spans the Conodoquinet Creek for 160 feet. A concrete bulkhead was added to the crib (stone filled) dam c.1920 when the dam was breached. The mill pond extends west of the dam for 2 1/2 miles. The working pond extends ¼ mile weat of the dam.

The main section of the mill measures 44 by 57 feet. It was likely originally built entirely of stone but flood damage over the years resulted in some of the walls being constructed with frame construction. The mill was modernized c.1920 and portions of a wall had to be removed to install two water turbines, gearing, and the hurst frame. A frame office building, storeroom were added to the east side of the building c. 1922. A small shed-roof brick addition to house the engine was added on the west side of the building. The mill retains its milling equipment and is virtually left as it was the last day milling operations were being conducted. The basement level retains the water turbine, hurst frame, crown gears and the line shafts and belt drives that conduct the poser to the upper floors. A fireplace is located in one corner where the miller would heat branding irons for the barrelheads. The roller mills located on the first floor were manufactured by the Wolf Company of Chambersburg. There are also a mill scale, bag packer, grain chutes, a pot belly stove and a large work bench on the first floor. The second floor includes storage bins for grains, a purifier, and animal feed mixer, an exhaust fan and a wheat-receiving separator. The attic level contains the tops of the elevators, bolting machinery and sifters and dressers, the dust collection system, and a purifier

National Register of Historic Places

Mr. Foshag had made application to list the Mill on the National Register of Historic Places, however, he was not able to fully complete that application. Based in large part on David Smith’s research and writings (see above) a revised application was filed and fully approved. David is shown on the right at the unveiling of the National Register Plaque at the Mill with Angie and Randy Heishman, Mill owners looking on.

Eva, Ian, Angie and Randy Heishman proud owners of the Diller Heishman Mill

William F. Foshag,Preservationist. August 28,1928 – April 27,2017

William Frederick Foshag (Willy) was the son of an internationally renowned geologist and an accomplished artist who grew up in the greater Washington D.C. area. His professional career as an aeronautical engineer involved design developments in Helicopters and Air Cushion Vehicles. Willy took possession of the Mill in 1969 and subsequently bought it outright in 1976. He spent the next 40 years of his retirement preserving and restoring the 200 year old Mill.

Images of the interior of the Mill

Traditional Rock Crib Dam at Diller-Heishman’s Mill

The full creek width Rock Crib Dam at Diller Heishman’s Mill was constructed in 1840 and replaced the previous wing dam. These dams were built with an interlocking structure of local logs and then filled with rocks. Sediment then filled many voids. The dams were designed NOT to block all water flow in order to reduce the risk of the dam being destroyed. Below is a picture of Mr. Foshag completing repairs to the dam in 1981, including replacing rocks and wood structure and installing a cement coating on the top and face of the dam. Note the coffer dam and pump to lower the water level. When the dam was threatened to be removed, Mr. Foshag designed and implemented a Fish Bypass Stream to allow the Rock Crib Dam to remain intact. See the Conodoguinet Creek Page for more details